Why MHEC is being preferred over HPMC for Cellulose Ether

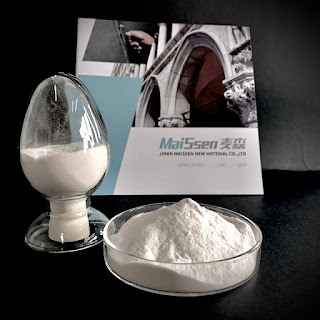

Cellulose Ether is derived from Cellulose and is a water-soluble compound used in several industries. It finds its usage mainly in the construction, food, pharmaceutical, and cosmetics industries. Specifically, Cellulose Ether is primarily used in the construction sector as it acts as a binder, thickener, and water retention agent in construction. There are different grades of Cellulose Ether, which have their applicability and properties. The two primary grades of Cellulose Ether HPMC (Hydroxypropyl Methyl Cellulose) and MHEC (Methyl Hydroxyethyl Cellulose) have varied similarities, yet one is more preferred than the other in recent days. Nowadays, MHEC grade of Cellulose Ether is more preferred than the HPMC grade in the construction industry. Though, both are being utilized widely for increasing bond strength and water retention capacity of a dry mixture of cement and gypsum, few properties differentiate them. The first property differentiating Methyl Hydroxyethyl...